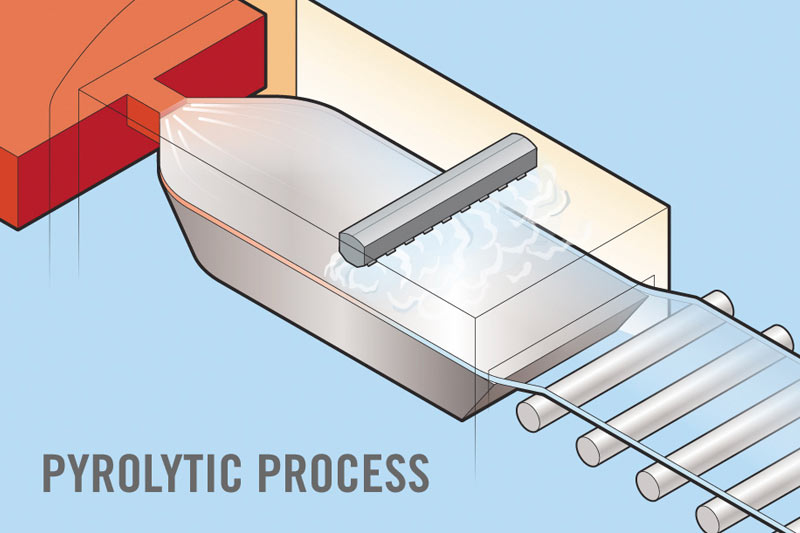

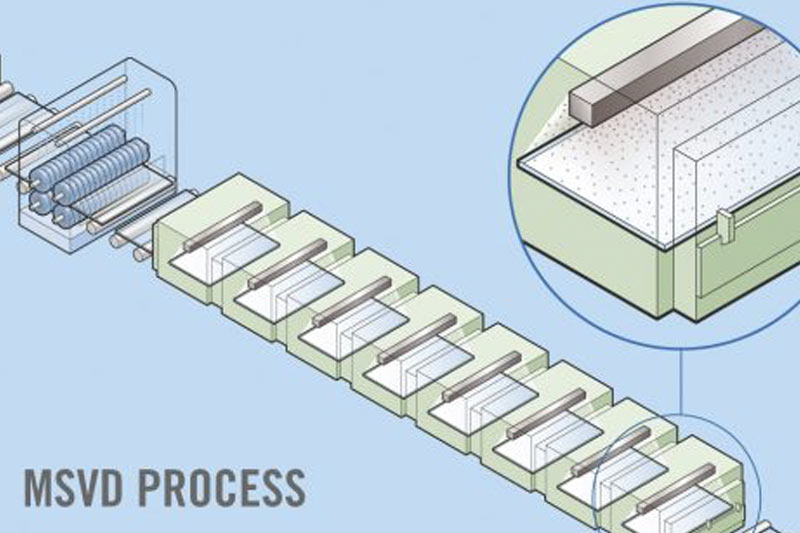

Toughened glass is physically and thermally stronger than regular glass. The greater contraction of the inner layer during manufacturing induces compressive stresses in the surface of the glass balanced by tensile stresses in the body of the glass. For glass to be considered toughened, this compressive stress on the surface of the glass should be a minimum of 69 megapascals (10,000 psi). For it to be considered safety glass, the surface compressive stress should exceed 100 megapascals (15,000 psi). The greater the surface stress, the smaller the glass particles will be when broken.

It is this compressive stress that gives the toughened glass increased strength. This is because any surface flaws tend to be pressed closed by the retained compressive forces, while the core layer remains relatively free of the defects which could cause a crack to begin.

Any cutting or grinding must be done prior to tempering. Cutting, grinding, and sharp impacts after tempering will cause the glass to fracture.

The strain pattern resulting from tempering can be observed with polarized light or by using a pair of polarizing sun glasses.